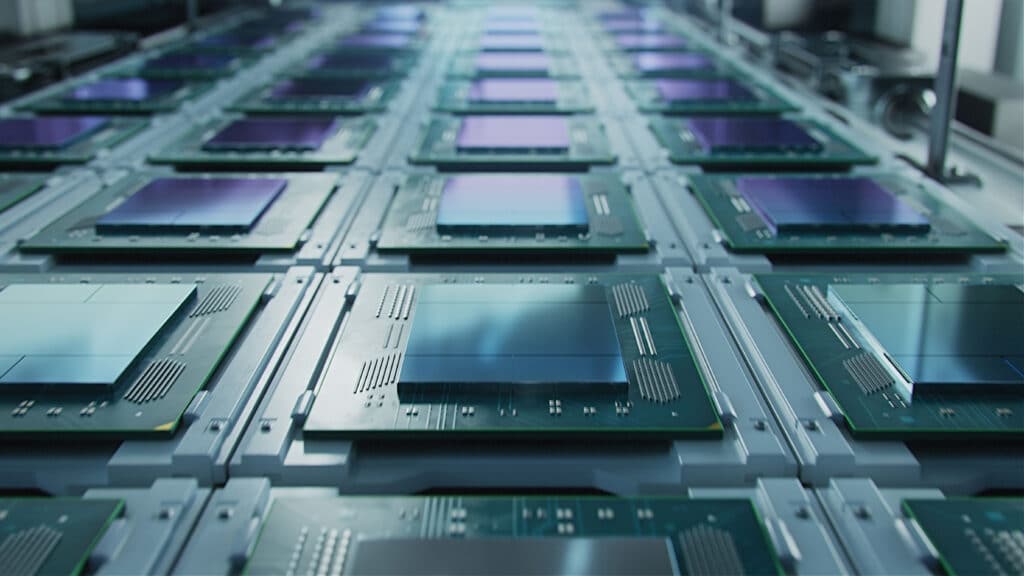

India currently depends on overseas suppliers for roughly 90% to 95% of its semiconductor requirements. That reliance is now prompting a major domestic push, as the government moves forward with plans to establish what it hopes will be the country’s first large-scale semiconductor fabrication plant. The facility is planned for Dholera, a special economic zone in the western state of Gujarat, according to Nikkei Asia.

Major investments signal industry takeoff

Tata Electronics has pledged $10 billion to develop India’s inaugural chip fabrication plant. In parallel, CG Semi — a joint venture involving Japan’s Renesas Electronics and Thailand’s Stars Microelectronics — is building a facility expected to scale up to producing 15 million chips per day, targeting the automotive, defense and industrial sectors.

Semiconductor market poised for rapid growth

India’s semiconductor industry is projected to expand sharply in the coming years. The market is forecast to grow from $52 billion in 2024 to $103.4 billion by 2030, according to estimates from the India Electronics and Semiconductor Association, underscoring the scale of domestic demand driving the push for local manufacturing.

Catching up after decades on the sidelines

India largely missed the early decades in which Taiwan, South Korea and China established dominant semiconductor ecosystems. Now, shifting geopolitical dynamics are creating new opportunities. Rather than seeking full self-sufficiency, New Delhi is pursuing a more pragmatic strategy — encouraging competition among state governments for investment, tapping strong bilateral relationships for technology partnerships, and committing significant public and private capital to build not only fabrication plants but the broader supply chain that supports them.

A critical test ahead

The next year to year and a half will be crucial. As India’s first commercial fabs begin production later this year, they will be judged by the industry’s toughest benchmarks, including yield rates, cost efficiency and product quality — factors that ultimately determine whether new entrants can compete in the global semiconductor market.